Process of ceramic best dissipation substrate by thin film & lithography process

Applying thin film deposition & lithography, fine circuit patterns can be formed on the ceramic surface. Electroplating can be then used to increase the thickness of circuit cued increase the capability of heat dissipation.

The composite processings increase the adhesion strength, dimension accuracy and smoothness of circuit trace. Thin film processing makes ceramic substrate more suitable for LED heat dissipation applications.

ICP Provides the following service:

- Thin film & lithography processing for Al2O3 high dissipated substrate.

- Thin film processing for Al2O3 high dissipated substrate.

- Thin film & lithography processing for AlN high dissipated substrate.

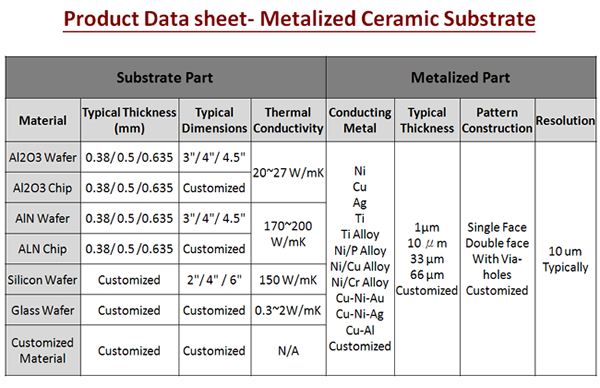

SPEC: